A broader product line accelerated product upgrade — Haitian Drive Systems participated in Shanghai Chinaplas in 2014

2014-04-23

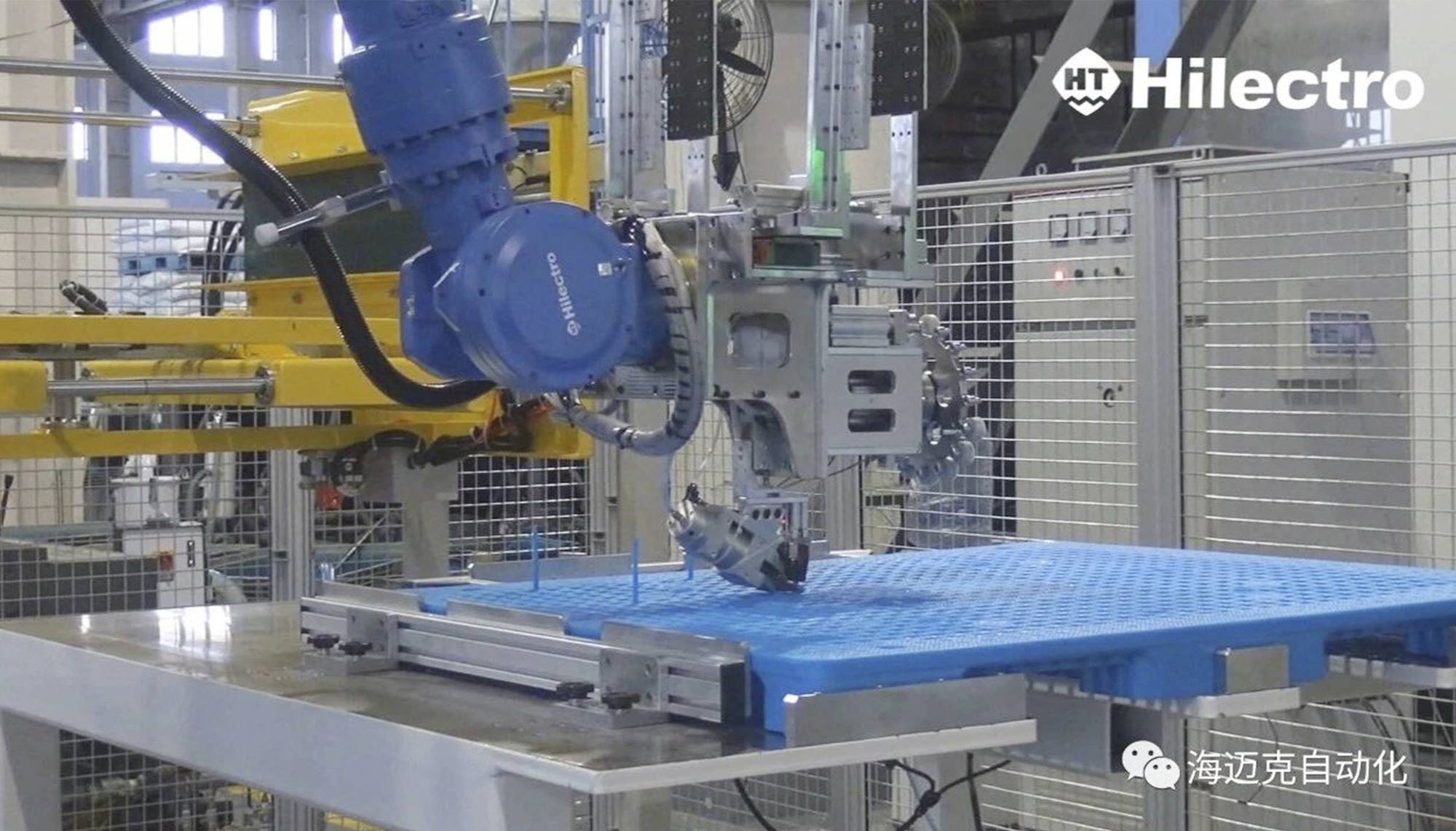

In the face of the fierce competition in the automation market, the Hilectro manipulator has emerged in recent years. With its rapidly improved technical content, excellent quality and timely after-sales service, it has been continuously recognized by the market. In 2013, the sales volume of Hilectro manipulator was nearly 70 million, and it kept increasing.

In 2014, Haitian Drive Systems launched XTD full servo series manipulator, which is suitable for injection molding machine of 800-4000 tons. This series of full servo manipulator has got rid of the restraint of frame structure, the movement is more flexible and reliable, and the range of applicable products is wider. The upper and lower units are manufactured with high-rigid aluminum profiles and designed with double cutting times speed and have compact structure. The travel of fixture clamping, fetching, releasing and entering and exiting the mold can be done at double speed at the same time, greatly shortening the work cycle and improving production efficiency.

At this exhibition, the demonstration scheme of Hilectro manipulator is as follows: Demonstration of terminal AC axis of XTA full servo manipulator arm, the demonstration scheme Includes the following aspects:

- Demonstration of quick change fixture: In the case that one fixture may not be able to complete

- Demonstration of advance: The main demonstration of full servo manipulator and five-axis linkage of AC shaft, and the arc linkage of the axis.

- Precision bevel positioning: Through the full servo manipulator and AC shaft linkage, the precise positioning on the ramp can be achieved.

In 2013, Haitian Drive Systems developed a new mold change unit of injection molding machine with the help of two major platforms of Haitian Plastic machine and Tecnomagnete S.P.A.. The product is safe and reliable, practical and efficient, energy saving and environmental protection, no maintenance and operation costs, and can be used for quick ring molds of various molds on one injection molding machine. It is especially suitable for multi-variety, small-batch and just-in-time mixed flow production. As soon as it is launched, it has caused rapid response in the market. At this exhibition, Haitian Drive Systems exhibited the embedded electric permanent magnet quick mold change magnetic template and covering magnetic template, which became the highlight in the exhibition.

Among them, the covered magnetic template is a new product created by Haitian Drive Systems and Tecnomagnete S.P.A. Company on the basis of embedded template and is specific to injection molding machine manufacturers. Compared with traditional magnetic template, this product has unique advantages:

- 37 mm thickness: The magnetic absorbing function of the back makes the magnetic template thickness of 37 mm not to affect the rigidity of the magnetic plate. Compared with the traditional magnetic template, it increases the mold stroke, reduces the expansion of ejection bar and injection nozzle to the maximum extent, and better controls the plastic temperature.

- Perfect combination with the mold: Molds, magnetic template and standard molding machine template are combined together by strong magnetic force, with absolute rigidity, avoiding vibration and deviation between each other, and improving the precision and quality of products.

- Using auxiliary templates: The mold covering magnetic template is divided into the magnetic template part and the auxiliary template part. The auxiliary template plays a role of protection and bearing on the magnetic template, and improves the interchangeability of the magnetic template.

At this exhibition, Hilectro Power Technology displayed the linear rolling guide and ball screw. As the high-precision functional component, the successful development and promotion of this product will fill the domestic gap.

At the same time, STF exhibited STF series and CTM series hydraulic motors at the exhibition, and the market response was good.

Through continuous integration, the company’s image, team cohesion, product quality and other aspects of Haitian Drive Systems are constantly improved The company’s two major brands, Hilectro and STF, have gradually gained a wider and loyal customer base through constantly improving product lines and continuously improving product quality. Haitian Drive Systems will adhere to the company’s entrepreneurial concept, and well interconnecting in innovation, energy conservation, high technology at all levels, and strives to open new areas in new areas, creating new glory.